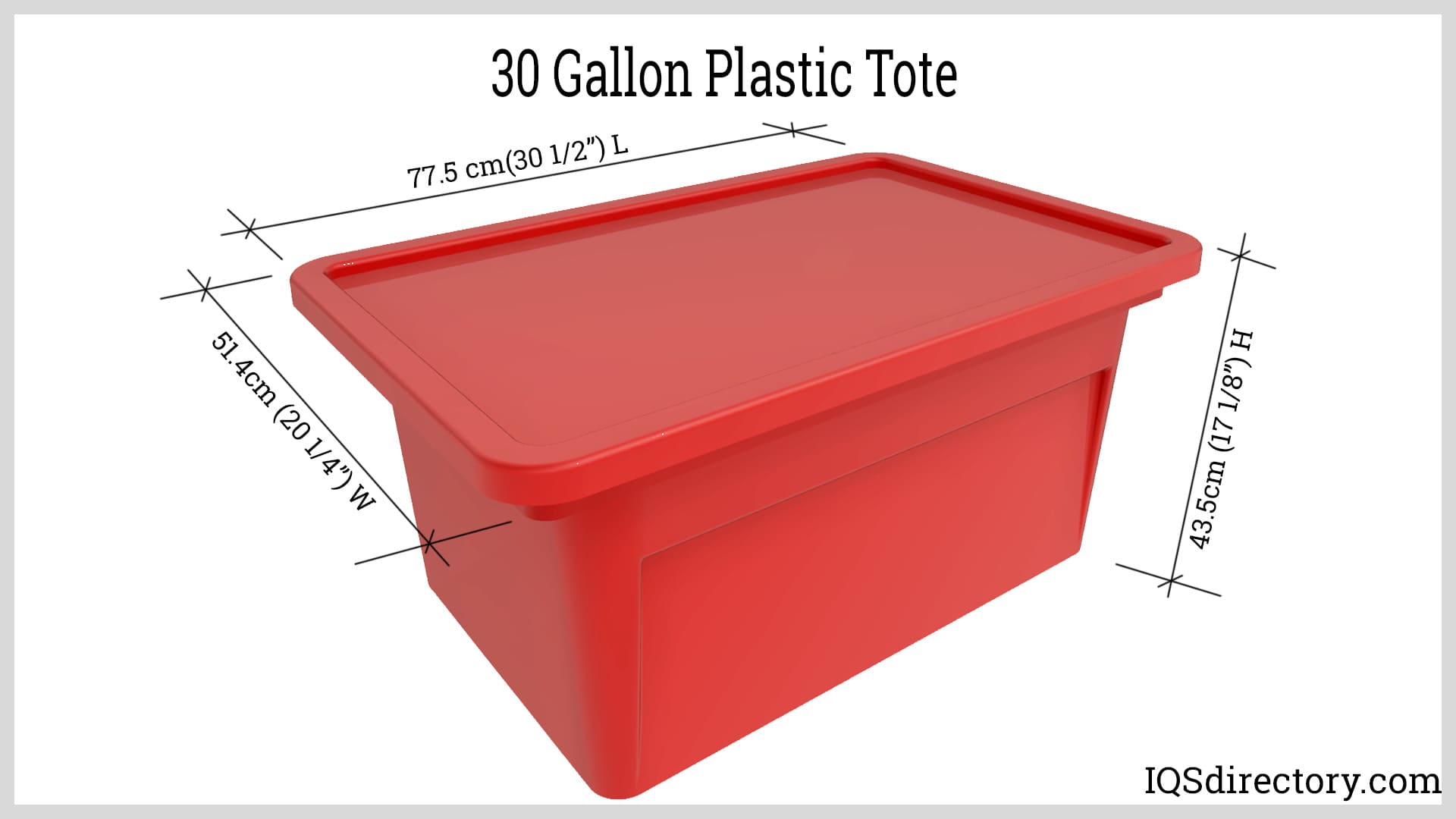

Totes are built in solid box shapes and are quite lucrative as industrial storage products that can be designed in a manner that allows them to be collapsed depending on the desired requirements to save space when they are not being used. Other plastic totes have hinged or removable tops, which can provide easy access for the user. Read More…

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Plastic Tote Manufacturers

Features of Plastic Totes

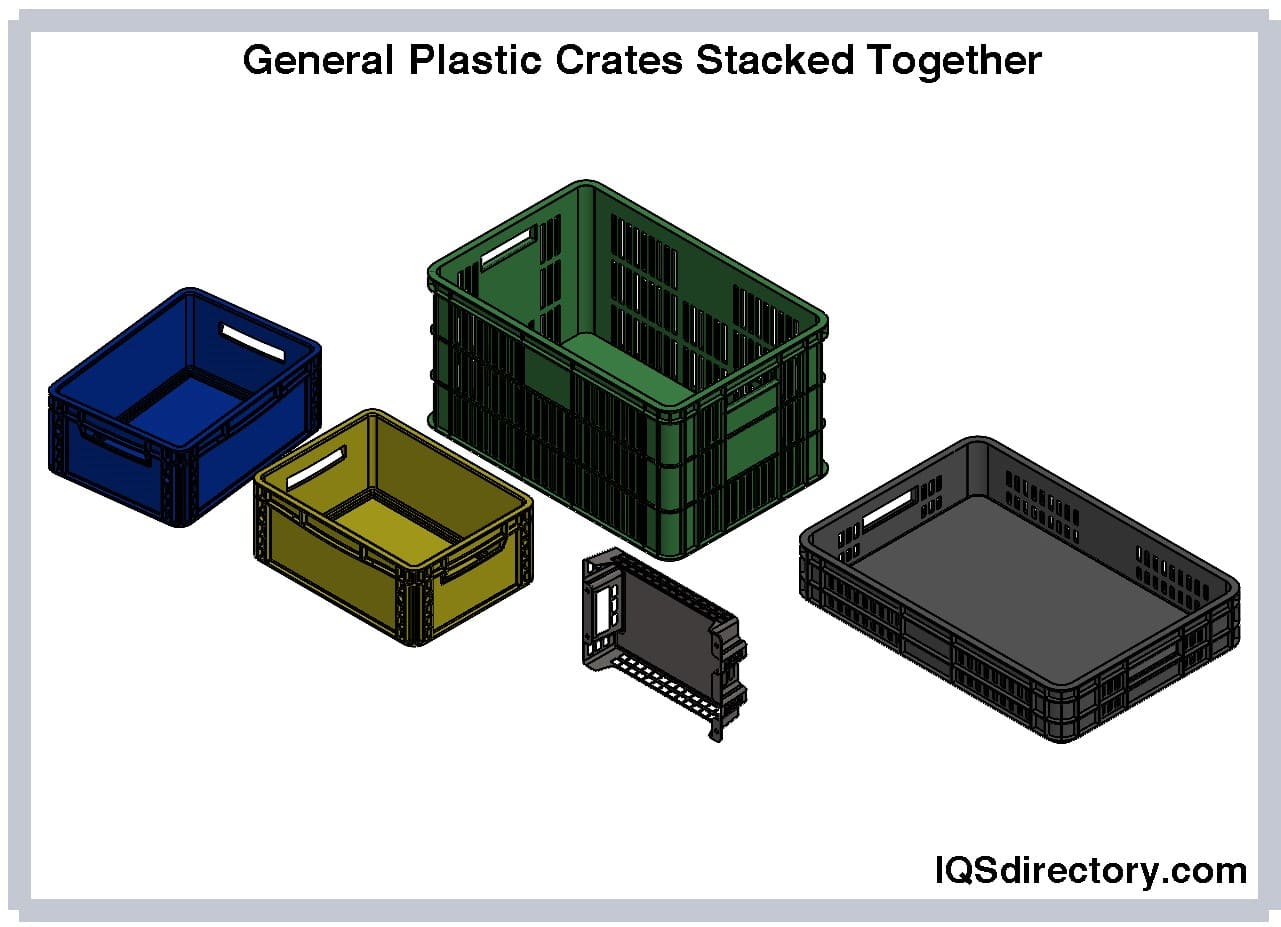

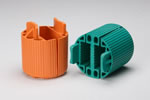

Totes have various features which depend on their use. Some are sized to accommodate automated processing equipment. Other totes are designed for heavy-duty use and come in different shapes, sizes, and colors. Some totes are made with built-in legs. Small totes are usually made in a manner that allows them to be stacked. Larger plastic totes may be designed with casters or openings that can coordinate with pallet jacks. Plastic totes are recyclable, may be insulated or uninsulated, and some are manufactured for use in the pharmaceutical industry and have to be approved by the Food and Drug Administration (FDA).

Types of Plastic Totes

- Bulk Totes – These kinds of totes are resistant to any form of eroding, rusting, warping, or splintering. These kinds of totes are best suitable for a varied kind array of food and materials.

- Insulated Totes – Insulated totes are best described by the name and offer insulation; therefore, they are best for controlling temperature and protection. They are manufactured in various shapes and sizes depending on their application.

- Collapsible Totes – They are available as solid or vented and are mostly used in material handling. They are collapsible, making them easy to store when they are not in use.

- Hand-Held Totes – They are easily stackable because they are smaller and are stable for space storage. They are used in various industries and businesses because of their great applications.

Plastic Totes Information/Product Specifications

In addition to the listing used to classify them above, totes additionally vary based on the following characteristics:

- Volume capacity

- Depth or length

- Width or diameter

- Height

- Color

- Material

Plastics Used to Make Totes

Generally, totes are made of plastic, fiberglass, wire, or metal. Acrylates, acrylics, polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) are the materials used to make plastic totes. Understanding material properties is necessary for making the best choice of goods. Acrylonitrile butadiene styrene (ABS) offers dimensional stability and is a stiff thermoplastic polymer.

There are many different colors, designs, thicknesses, and sizes of acrylic totes. Though PE and PP are typical thermoplastics, polypropylene offers significantly higher corrosion and crack resistance levels. Because PVC is inert, it is frequently utilized in totes and containers for the food and chemical processing industries.

Benefits of Using Plastic Totes

- They are easy to install if they are collapsible and have vast space; therefore, they are easy to use.

- They are very cost-effective because they help save money by executing supply chain costs.

- They are of great use in separating materials when storing different arrays of small items, for example, bolts, nuts, and screws.

- Plastic totes offer safer storage solutions because they can be easily accessible in their time of need.

- They are space preservers because they can be stored on top of each other during use. They can also be stacked therefore saving space when not in use.

- Plastic totes are environmentally safe because they do not cause pollution and offer sustainability.

- They are a long-term storage solution which is quite advantageous.

- Plastic totes have a lid that swings open and closes, which allows them to be locked for security and tamper-proof applications. In addition, some totes come with molded legs.

Applications of Plastic Totes

Regarding the application of totes, they are used for storing materials in various manufacturing industries, parts organization, distribution, and shipping. Plastic totes are also used for storing and moving seafood, poultry, fruits, vegetables, and meat. They are also used in the pharmaceutical and electronic industries.

Choosing the Correct Plastic Tote Manufacturer

To ensure you have the most productive outcome when purchasing plastic totes from a plastic tote manufacturer, it is important to compare several companies using our directory of plastic tote manufacturers. Each plastic tote manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each plastic tote business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic tote companies with the same form.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services