Plastic containers are enclosures fabricated from plastic that are made to contain items. They are staple of modern life and provide cheap storage for both industrial suppliers and economic consumers. Plastic containers are characterized by a wide variety and can be found in every major industry. Read More…

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Plastic Container Manufacturers

History of Plastic Containers

Plastic (a man-made, synthetic version of natural resins) first appeared in 1862. At an international exhibition in London, Alexander Parkes introduced an early version of plastic derived from cellulose. Thirteen years later, plastic first appeared in the form of bottles. Early in the twentieth century, the first fully synthetic bottles also appeared. Plastic bottles provided an alternative to glass and ceramic, which had been used for bottles from ancient times. These breakthroughs, however, did not make a major economic impact due to high production costs. As a consequence, plastic packaging did not begin to truly develop until about the mid-twentieth century.

In 1946, Earl Tupper pioneered the use of polyethylene food containers that are better known today as Tupperware®. These convenient and airtight inventions proved popular among American housewives and marked a major milestone in the history of plastic packaging. Around the same time, Dr. Jules Monteniener popularized the use of plastic bottles by introducing an underarm deodorant known as “Stopette.” Polyethylene bottles appeared in the 1960s and remain the leading type of plastic bottle today. With regard to more specific types of bottles, the two-liter plastic bottle and single gallon jug widely used today for beverages and milk (respectively) first became widespread in the 1970s.

In the 21st century, plastic containers remain as popular as ever. Some steps have been taken to return to bio-based plastic packaging. An example is the introduction of polylactic acid (PLA), a corn-based plastic used for containers.

Production of Plastic Containers

The vast majority of plastics are made of hydrocarbons that are processed and refined through specialized methods that are applied to petrochemicals. Raw materials derived from crude oil and natural gas are refined and converted into materials such as vinyl chloride, glycol, ethylene, and styrene. All of these ingredients are, in fact, the main components of thermoplastics. Since thermosetting plastics cannot be remolded once set, they are not as commonly used in manufacturing. Some specialized types of plastic containers exist, such as biodegradable containers made from processed corn. Most plastic containers, though, are made from some type of thermoplastic by standard plastic manufacturing processes.

The production of plastic storage boxes is currently one of the most developed economic sectors. It can be claimed that almost every product sold today depends in some way on the development of plastic packaging. Plastic storage boxes are required in a plethora of industries, especially to store raw materials and products, to carry stuff, and also for packaging. Not only do these plastic storage boxes protect the material in them if it is fragile, but these containers also make it easy to transport various objects over extended distances.

Injection molding is the main plastic formation process used for thermoplastics. It involves inserting thermoplastic resins (in pellet form or otherwise) into a machine known as a “hopper.” A large screw forces the thermoplastic resins through a heated passageway and ultimately shoots molten plastic into a mold in order to assume a certain shape by hardening once it has cooled. Blow molding is a similar process to injection molding. The main difference between the two processes lies in the fact that blow molding uses compressed air as well as the shape of the mold to obtain a certain form. Blow molding is sometimes preferred for a higher degree of uniformity (e.g. when manufacturing bottles).

Types of Plastic Containers

Since they can be classified in such a multitude of ways, there are too many kinds of plastic containers to lump them into one universal description. Among all of the varieties of plastic containers, however, they do share some fundamental properties in common with one another. On a slightly simplistic level, plastic containers can be simply defined as any type of plastic enclosure whose primary purpose is to store items. It should be noted that this applies to both containers which are primarily open-ended (e.g. bowls) as well as containers that are typically completely closed (e.g. jars).

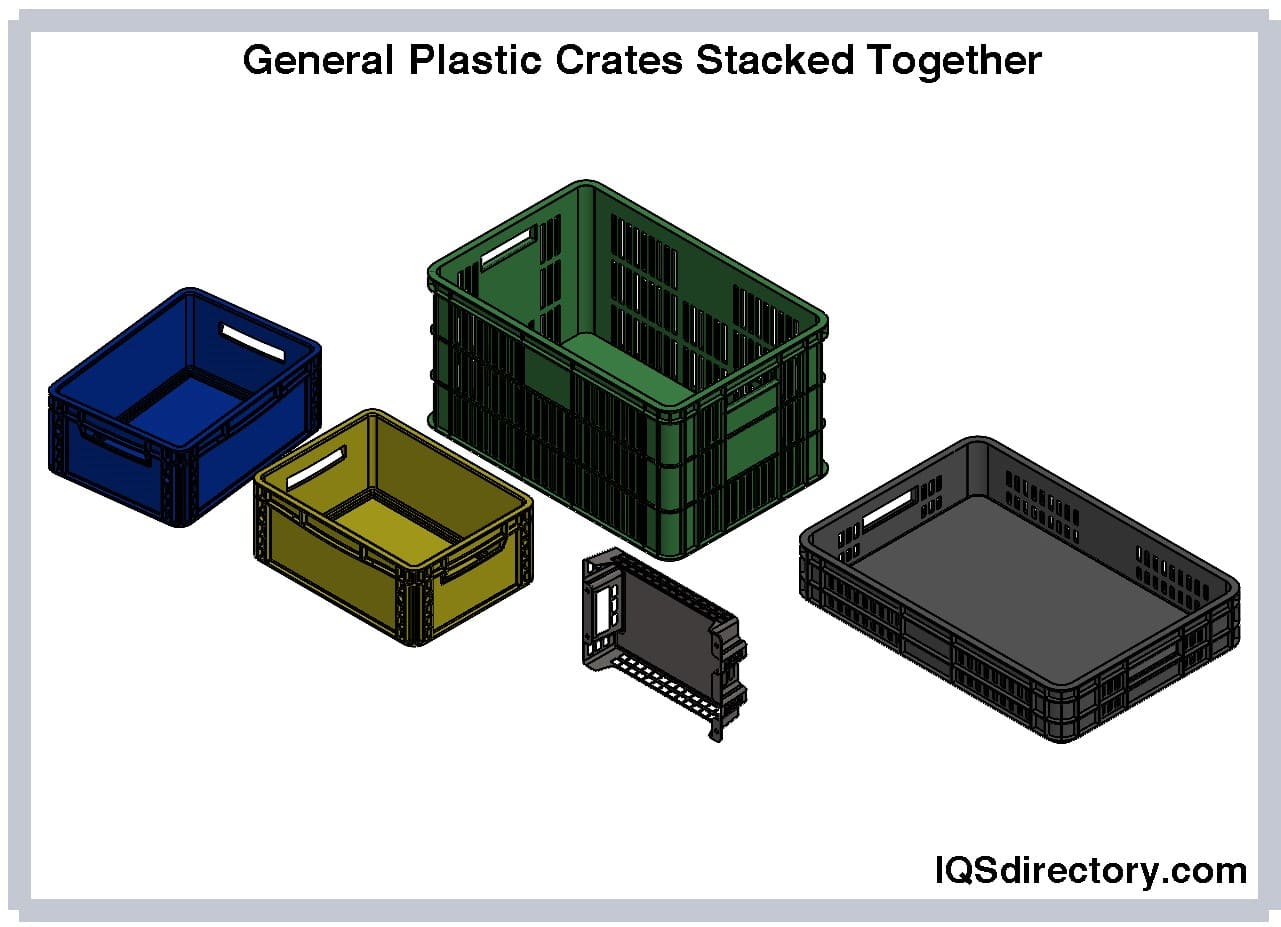

Plastic containers can be categorized according to their shape, size, application, or function. Most likely, the easiest way of categorization analyzes plastic containers according to their shape or form. Plastic containers appear in the form of bottles, jars, cups, bowls, cartons (e.g. for eggs), pails, cans, squeeze tubes, trays, basins and bins, among many others. Plastic bottles and jars are especially popular. In 2011, they represented a little over three-quarters (77%) of all plastic containers used within the U.S. (based on overall total pounds). Despite lacking a rigid structure, plastic wraps are also often considered part of the plastic container category.

The chemical makeup of a plastic container is another common way of categorization. The thermoplastic polyethylene is by far the most common material used for plastic containers. Polyethylene terephthalate (PET or PETE) is highly valued for its resistance to moisture and breakage. As a result, it comprises 96% of plastic containers consumed within the U.S. Chemically speaking, other types of plastic containers include:

• High density polyethylene (HDPE) containers (strong containers such as medicine bottles or laundry detergent containers)

• Low density polyethylene (LDPE) containers (such as squeeze bottles containing condiments)

• Polyvinyl chloride (PVC) containers (such as food trays or plastic wraps)

• Polypropylene containers (often used for fruit and vegetable packaging and including the Nalgene drinking bottle)

• Polystyrene containers (rigid types often used for transporting food, such as yogurt)

Applications of Plastic Containers

Plastic storage boxes have a long list of industries where they are used. Below are some of the industrial areas which employ plastic storage boxes:

- Beverage

- Food

- Pharmaceutical

- Cosmetics

- Household consumer goods

- Industrial lubricants

- Petroleum products

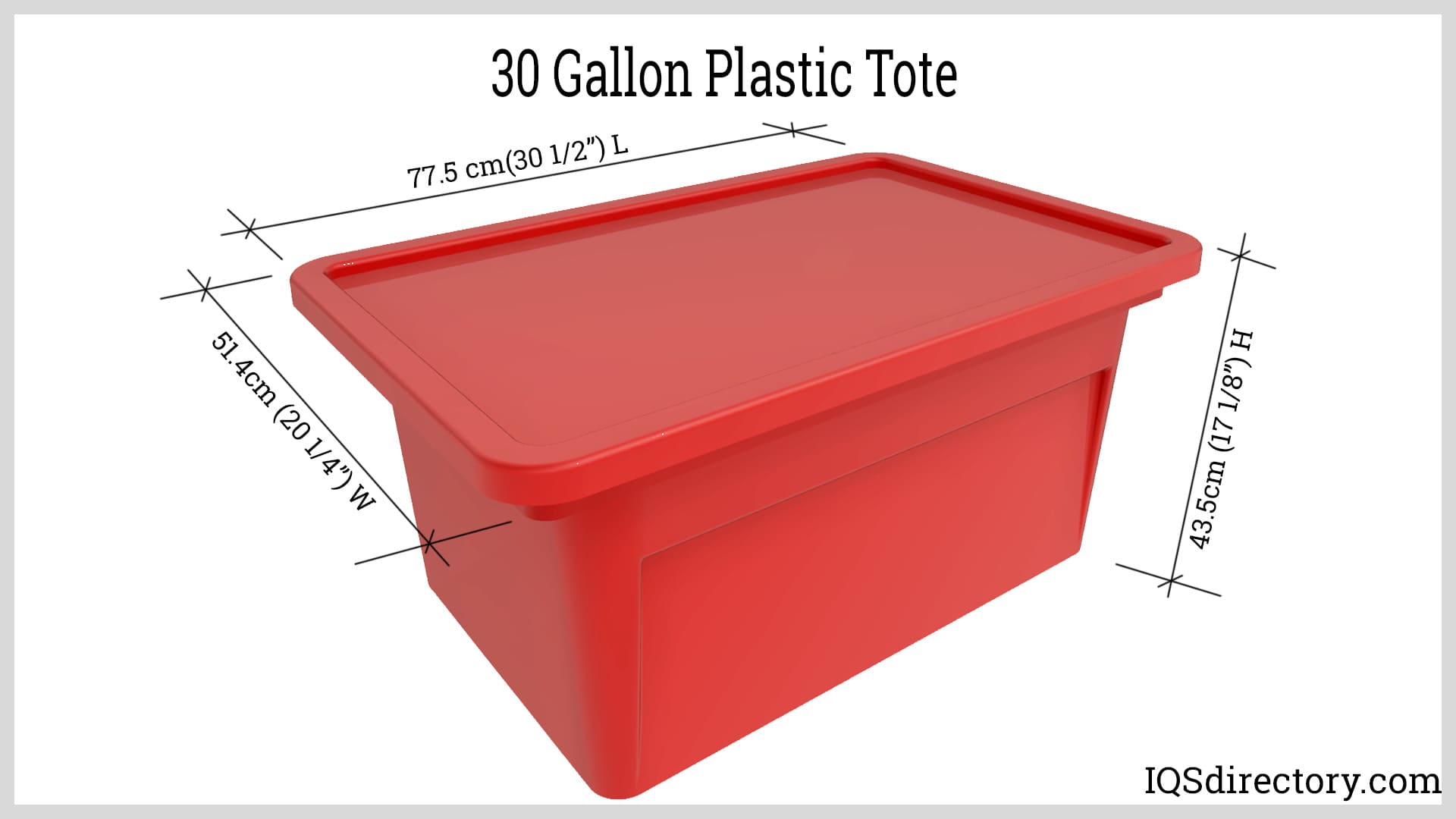

In simple words, a plastic storage box or container is a box used to carry, store and protect material. The material can be any raw material, a finalized product, or a fragile item. Plastic storage boxes are also available in large sizes (also regarded as plastic bulk containers) and they provide assistance to their users by allowing more room for any enclosed material to be protected, carried, or stored.

Plastic materials have been used in more applications across a broad range of industries than any other material. Naturally, then, plastic containers have found a plethora of similar applications across many different sectors of commerce. In the modern industrial age, it is difficult to think of how these applications can be achieved without plastic containers, even in scenarios where their function is limited. Many nations across the planet, regardless of economic development, utilize plastic containers in some way. Plastic containers are just as easy to come by in the city streets and rural roads of sub-Saharan Africa as they would in North America. Most people in developed countries will not likely remember a time when they have not used a plastic container, such as a plastic tub or a baby bottle.

Since plastic containers are fundamentally used for cheap and convenient storage, food packaging is one their primary uses. In underdeveloped areas of the world where food is scarce and there is no municipal water source, plastic containers are essential for everyday life, and are thus in high demand. In developed countries, it is rare to find a food container that is made of a material other than plastic (such as peanut butter in a glass jar). Some examples of food-specific plastic containers are bulk containers and freezer containers. Food packaging is a main factor in the high usage of plastic bottles and jars. It is also a main factor behind the popularity of plastic wraps, which effectively preserves the freshness of food.

Plastic containers are vital to many industries besides food packaging. In the pharmaceutical or medical fields, they are essential for transporting medicines and other specialized chemicals. In the construction industry, plastic pails provide a convenient way to transport materials such as paint and adhesives. In the landscaping industry, plastic catch basins are used to direct the flow of rainwater and to protect water sources from pollution. Industrial warehouses use plastic bins or totes to transport and store materials, and factories collect items from the production line using plastic tubs. Ironically, plastic bins are even used to recycle other plastic containers.

Advantages of Plastic Containers

There are numerous benefits of using plastic storage boxes or containers. A few important ones are briefly discussed below:

- Cost Savings

By lowering supply-chain expenses, switching from disposable cardboard boxes to reusable plastic trays will help you save money. Due to its versatility, each plastic box can easily replace hundreds of individual cartons. Additionally, they are a lot stronger. These containers don’t require maintenance, don’t cost as much to install or dispose of, and can be used to conserve space for return shipments.

- Space Savings

It is simple to discover these may be the ideal containers for any warehouse space because plastic storage boxes and containers come in a huge variety of sizes and designs, including stackable bins with interlocking sections.

- Protection

If you want to protect the integrity of the goods being stored in your warehouse, stackable plastic boxes with lids can assist with keeping dust and other debris from getting inside these containers and potentially damaging the contents inside.

- Long-Lasting Protection

Plastic storage boxes and bins offer a durable storage solution that will not be as easily harmed by environmental factors as compared to cardboard boxes and hardwood storage units. The materials used to make plastic storage containers are strong, light, high-density, waterproof, and UV-resistant.

Plastic, as a whole, is highly valued for its many efficient properties. Plastic is capable of being manipulated or shaped into any configuration possible. Additionally, it is light but strong and durable. Its low production cost seals plastic’s position as a preferred material for industry.

The versatility and customizability of plastic are its most relevant qualities with regard to plastic containers. Since plastic containers are primarily intended for cheap and convenient storage, it is essential that they be versatile in order to accommodate contents of many different shapes and sizes. Plastic containers for storage possess a high degree of this needed versatility.

Disadvantages of Plastic Containers

Although plastic containers have many advantage, they are not flawless. The containers are made from crude oil, and because the worldwide demand for plastics is so high, so is the demand for oil. This high demand can have negative environmental implications.

Plastic products can be detrimental to our planet if not properly disposed of. PVC, for example, possesses the unfortunate combination of being economically popular as well as a highly toxic to the environment. Besides chemically threatening the environment, PVC can threaten the environment in physical ways (e.g. plastic wrap entangling and killing coral in the Pacific Ocean). Although not overtly dangerous (such as steel products), plastic products may pose a long-term threat to human users as well. In recent years, concerns have been raised about the effects of synthetic compounds in plastic containers such as BPA.

There have been improvements in the recyclability of plastic products. For example, the poundage of recycled plastic bottles has increased every year since 1990. It is imperative for consumers to dispose plastic products in a way that keeps waste to a minimum. Unfortunately, it has been difficult for governments and businesses to enforce good recycling habits. Currently, best solutions to the problem of plastic waste disposal and eliminating waste are increased usage of safer plastic products (e.g. LDPE wrap over PVC wrap) and continued research on alternatives to hydrocarbon-based plastics.

Plastic Bottles

Packaging is always as crucial as the product itself. It should be presentable as well as safe for transport and consumption. Plastic containers and bottles are the ideal packaging material for products meant for consumption. Beverages and liquid contents especially are easiest and safe to move in disposable plastic containers.

It is not only the product’s safety but also its presentation. Plastic packaging enables manufacturers to post catchy designs and branding on the bottles for marketing purposes. Plastic is usually recyclable and reusable, making it an environmentally safe choice.

How are Plastic Bottles Manufactured?

Plastic bottles are made of different materials depending upon the type of properties of the end products. Usually, single-use plastic bottles are made up of Polyethylene Terephthalate(PET). While the bottles which are recyclable and can be used again are made up of Polypropylene (PP) or Polyvinyl Chloride (PVC). Usually, disposable and reusable plastic bottles have a slightly different manufacturing process.

Types of Plastic Bottles

Plastic bottles and liquid containers are categorized based on their composition. Following are some of the widely used types of plastic bottles/containers used nowadays:

Single-use Plastic Bottles: The temperature is set at 500 degrees Fahrenheit to melt the plastic and mold it into the desired shape. Usually, recycled PET is mixed into new PET, but mostly new raw material is used. Once cooled and shaped, these cannot be reheated or remodeled. These types of plastics are also called thermosetting plastics.

Reusable Water Bottles: Plastic is usually melted at lower temperatures, i.e., 150-350 degrees Fahrenheit, to shape. Afterward, these can be reheated and remodeled. These types of plastics are known as thermoplastics. These can be recycled as well.

PET Plastic Bottles

Polyethylene Terephthalate is a type of polyester that is usually derived from natural gas or crude oil. It is transparent like glass but is shatterproof, so it is safer. In contrast to glass, it is very lightweight and durable. It is also resistant to microbial growth; hence is usually used to bottle beverages and carbonated drinks.

Polyethylene (PE)

This category comprises all types of PEs used in plastic bottle manufacturing, i.e., High-Density Polyethylene (HDPE), Medium Density Polyethylene (MDPE), and Low-Density Polyethylene (LDPE).

HDPE: It is a thermoplastic and can be recycled into new products. It is translucent and resistant to moisture and vapors. It does not react with products, so it is ideal for both beverages and personal care products like detergents, soaps, etc.

LDPE: Plastic bottles made up of LDPE are very flexible and tough. These are resistant to heavy impacts and corrosion. So they are a very reliable choice for sterilized or expensive products.

MDPE: It combines both HDPE and LDPE; hence, it has more flexibility and is less translucent. It is widely used in manufacturing squeezy plastic bottles.

Polypropylene (PP):

It is a thermoplastic polymer and opens up the possibility of colored bottles or containers due to its opaqueness. It is lightweight and extremely resistant to heat. That is why it can be used to package products that need sterilization, e.g., food and beverages, cosmetics or medicines, etc.

Bioplastics:

Bioplastics are processed by using organic raw biomass from animals and plants. It is very sustainable and environmentally friendly. These are very safe options for food and beverage packaging. These also can be used in the agricultural industry to transport products.

Why Use Plastic Bottles?

Plastic containers should be used to package food and beverages, cosmetics, pharmaceutical, and agricultural products because these are

- Long-Lasting and resistant.

- Reusable.

- Less expensive as compared to common alternatives available like glass.

- Flexible and safe.

- It can be molded and shaped.

- It can be a great medium for branding.

Considerations for Working with Plastic Container Suppliers

Some standard business considerations apply when searching for a plastic container supplier or plastic container manufacturer. The appearance of plastic is deceptively simple. It is important to keep in mind, however, that plastic production as a whole is an extremely sophisticated process requiring a deep knowledge of chemistry and related areas. Thus, you should invest in finding a plastic container supplier with an experienced track record of high quality plastic production. You should invest in finding a supplier who possesses both the knowledge and willingness to advise you on specific container applications. Become educated on the methods your supplier undertakes in order to produce a certain application (e.g. blow molding in order to increase uniformity). Because plastic’s main disadvantages are largely environmental, it is worth investigating your plastic container supplier’s level of commitment to mitigating these effects. Consider discussing with your supplier their recycling practices as well as recommended practices for properly using and disposing of your plastic containers.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services