Catch basins are typically nestled into the entrance of a drain so that its top is flush with the surface, though basins with curved or arched upper filter surfaces are also used. Read More…

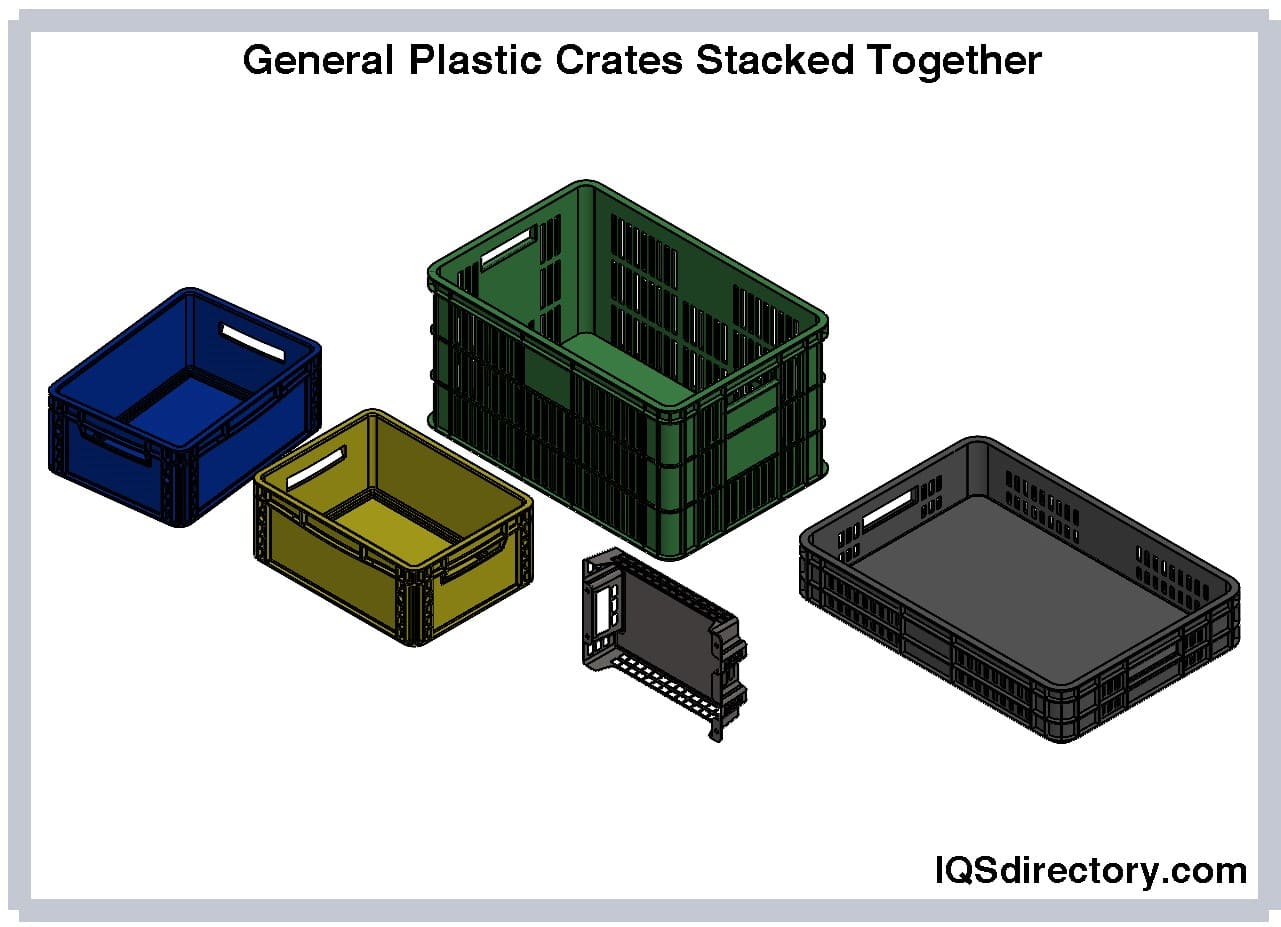

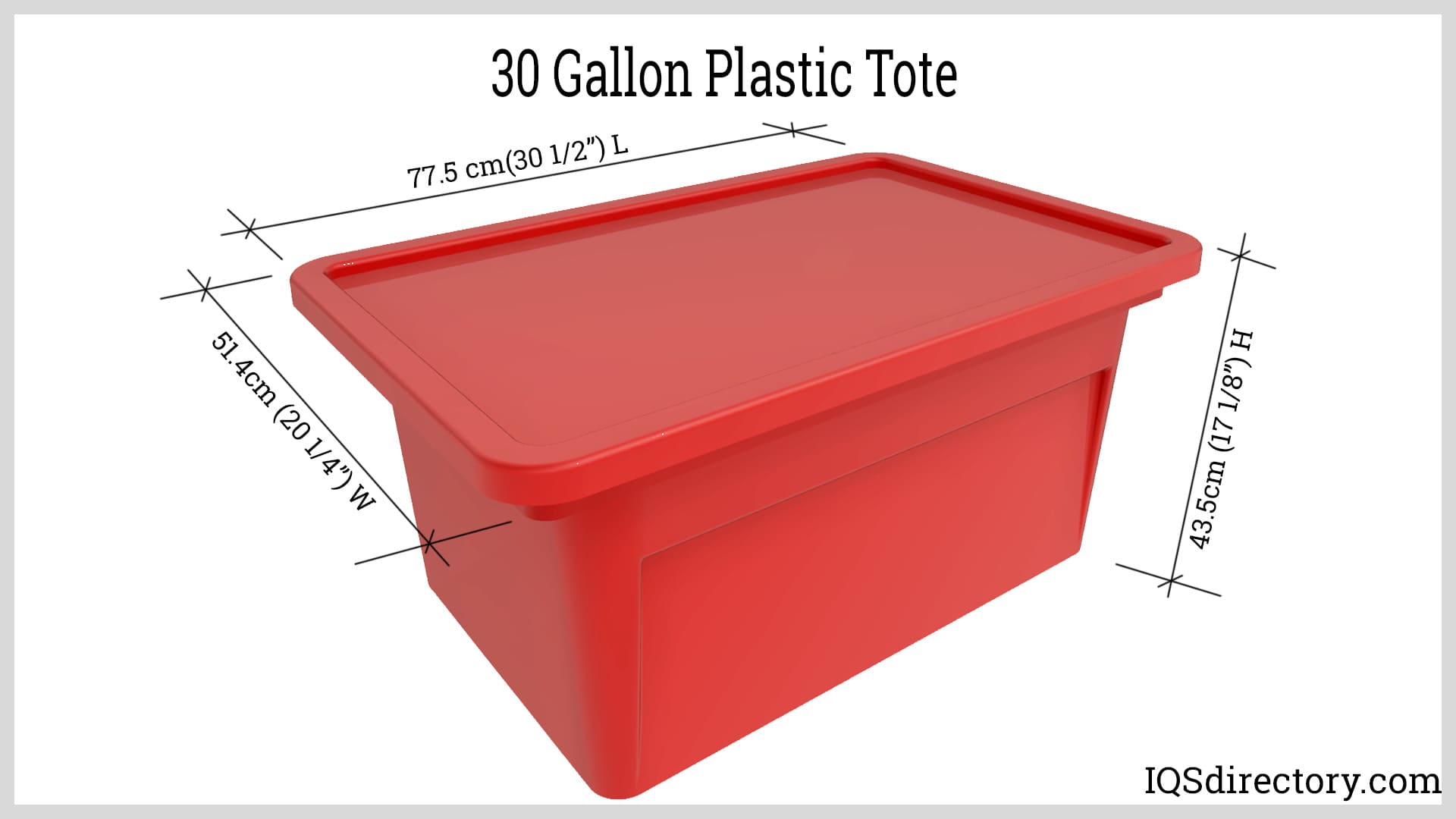

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Catch Basin Manufacturers

Catch basins are important in preventing lake, river and water table pollution by stopping solid materials from clogging drainage systems or by passing through them into bodies of water.

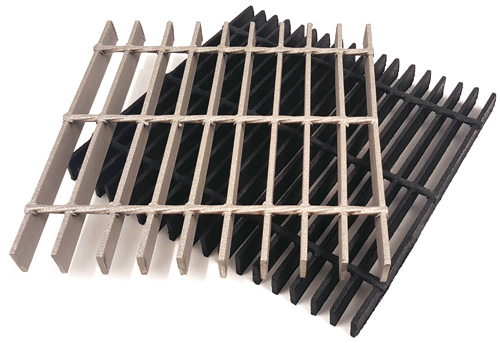

All catch basins have two or more openings; the opening at the top allows for the collection of water and debris, though this opening often features a grid or lattice pattern to prevent the entrance of overly large debris. The other opening or openings are for the actual drained water to exit. These openings are usually covered with another filter; this can be an integral filter or a metal mesh filter that can be removed for cleaning or replacement.

The bottom of the basin features a recession of variable volume which catches and holds debris that should not enter the drainage system. Catch basins are also widely used in home landscaping applications, typically at the entrance to runoff or standing water drainage systems. In that context they prevent small-scale drainage systems from becoming clogged, thereby reducing or eliminating their effectiveness.

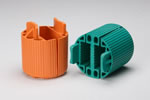

Plastic catch basins are more lightweight and inexpensive than metal or concrete catch basins. This makes them easier to install, and for that reason they are popular in consumer drainage system applications. Plastic catch basins are created by plastic injection molding. Injection molding processes begin with a collection of raw plastic materials, or stock, loaded into a hopper. The hopper releases the stock into a conveyance channel where a long screw pushes the stock toward a mold.

A mold is a cavity that, when filled with molten plastic material, creates plastic shapes. After being pressurized and heated in the conveyance channel, the molten plastic is forced into the mold where it is shaped. Then, under carefully controlled conditions, the molded plastic is allowed to cool and harden. At this point, the plastic is cleared of imperfections (if they are present) and then shipped or sent to additional processing.

Plastic basins differ from other plastic containers in that once they are installed, they are intended to function permanently. Unless they are damaged by shifting soil, vehicles passing overhead or if they fail for another reason, they continue to serve their single purpose indefinitely.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services