Plastic bins differ in function and design from plastic food containers. Plastic bins are not used for storing and distributing food items; rather, they are used for storage of small items in various facilities such as warehouses, workshops, offices, etc. These bins can be mounted on a wall or rack, or can be hung from panels. Read More…

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Plastic Bin Manufacturers

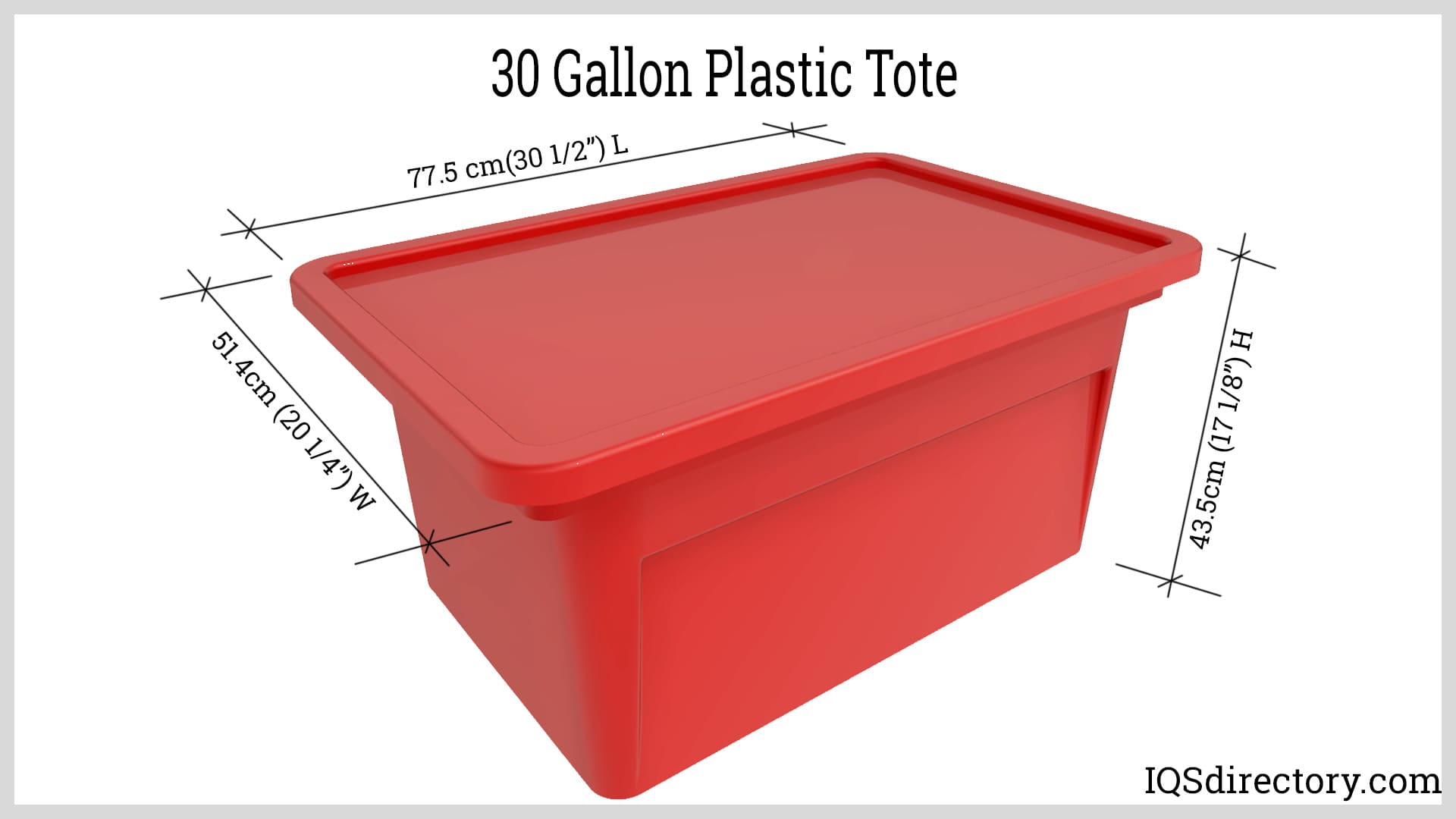

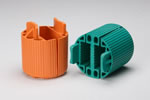

Plastic bins or containers are made from various forms of polymers that are produced from crude oil or natural gas. Different chemical and physical processes are done to make strong, sturdy, durable, and long-lasting containers according to requirement. Different types, shapes, and sizes of plastic containers are used for storing or transporting different kinds of products.

Plastic Materials Used

Different types of plastic materials are used for making plastic bins or containers. Usually, these containers are marked with a number at the bottom. This number is the type of plastic that is used in its making. Following are the plastic types used for manufacturing bins:

Polyethylene Terephthalate

PET is the most commonly used for containers such as carbonated bottles. It is a safe plastic and can be recycled to make other useful applications.

High-density Polyethylene (HDPE)

HDPE is a stiffer plastic material used for making water gallons, milk jugs, detergent bottles, and plastic drums or containers. This material can be reused and recycled, making it a safe one.

Polyvinyl Chloride

PVC is also a plastic type that makes rigid and flexible plastic containers by modifying plasticizers.

Low-density Polyethylene

This is a type of PE with lower tensile strength and barrier properties. This material is good for making flexible containers, squeezable bottles, and sampling bottles.

Other types of plastic materials used for making containers are polypropylene, polystyrene, polycarbonate, nylon and acrylonitrile butadiene styrene. All these types have specific properties and are used for making plastic containers or bins.

Manufacturing Methods of Plastic Bins

The manufacturing methods for plastic containers differ depending on the type that is being made. Following are the common methods:

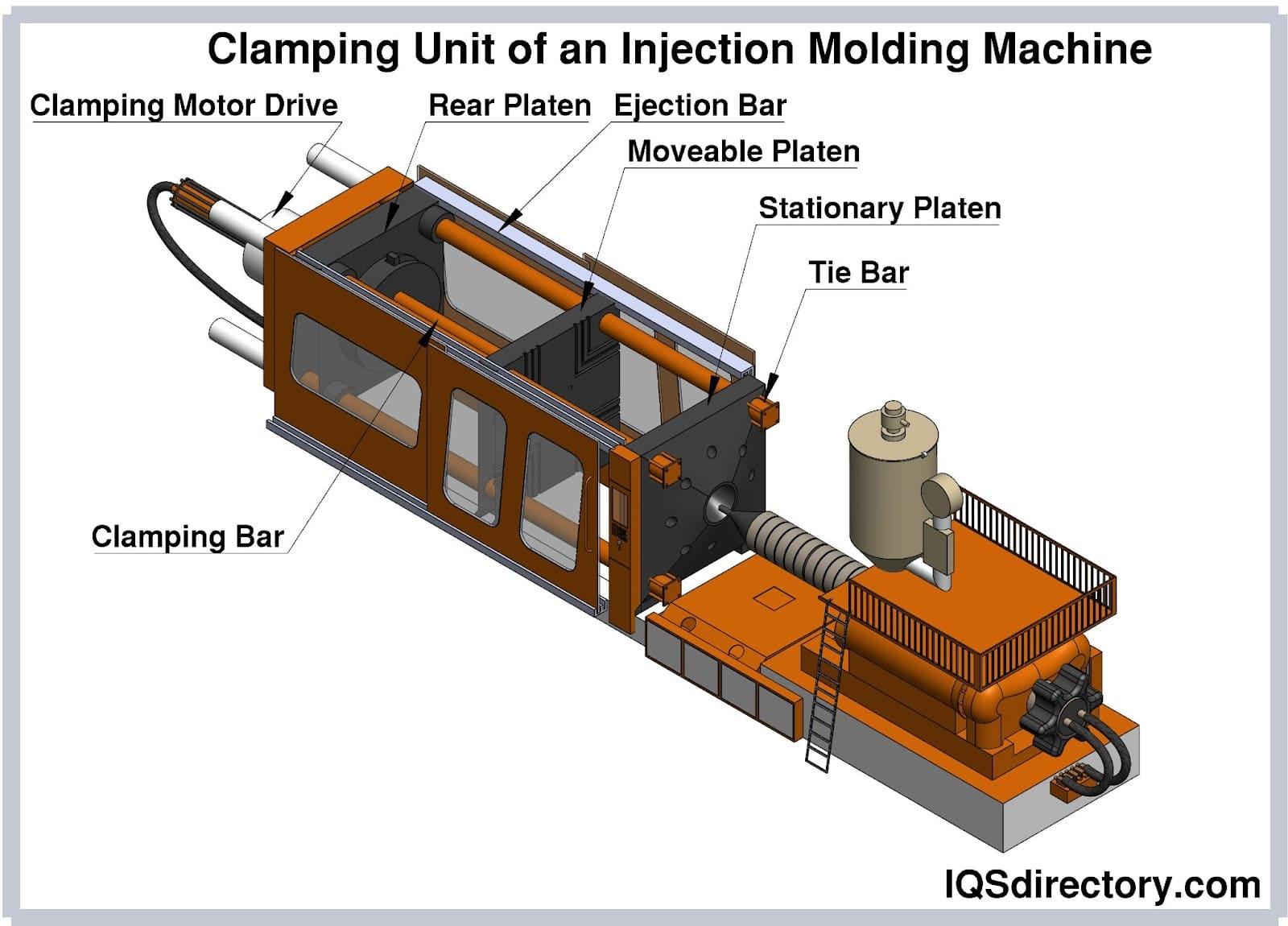

Injection Molding

Injection molding is done by injecting molten plastic into a closed chamber or mold. Once the plastic is cooled down it is then opened to eject the plastic container. The mold takes the shape of a plastic container, which is composed of two halves: one is stationary and the other one is moving. Examples are pails, tubs, cups, bowls, and food containers. Inert gasses are introduced into partially shaped molten plastic; the gas creates a hollow part on the mold surface.

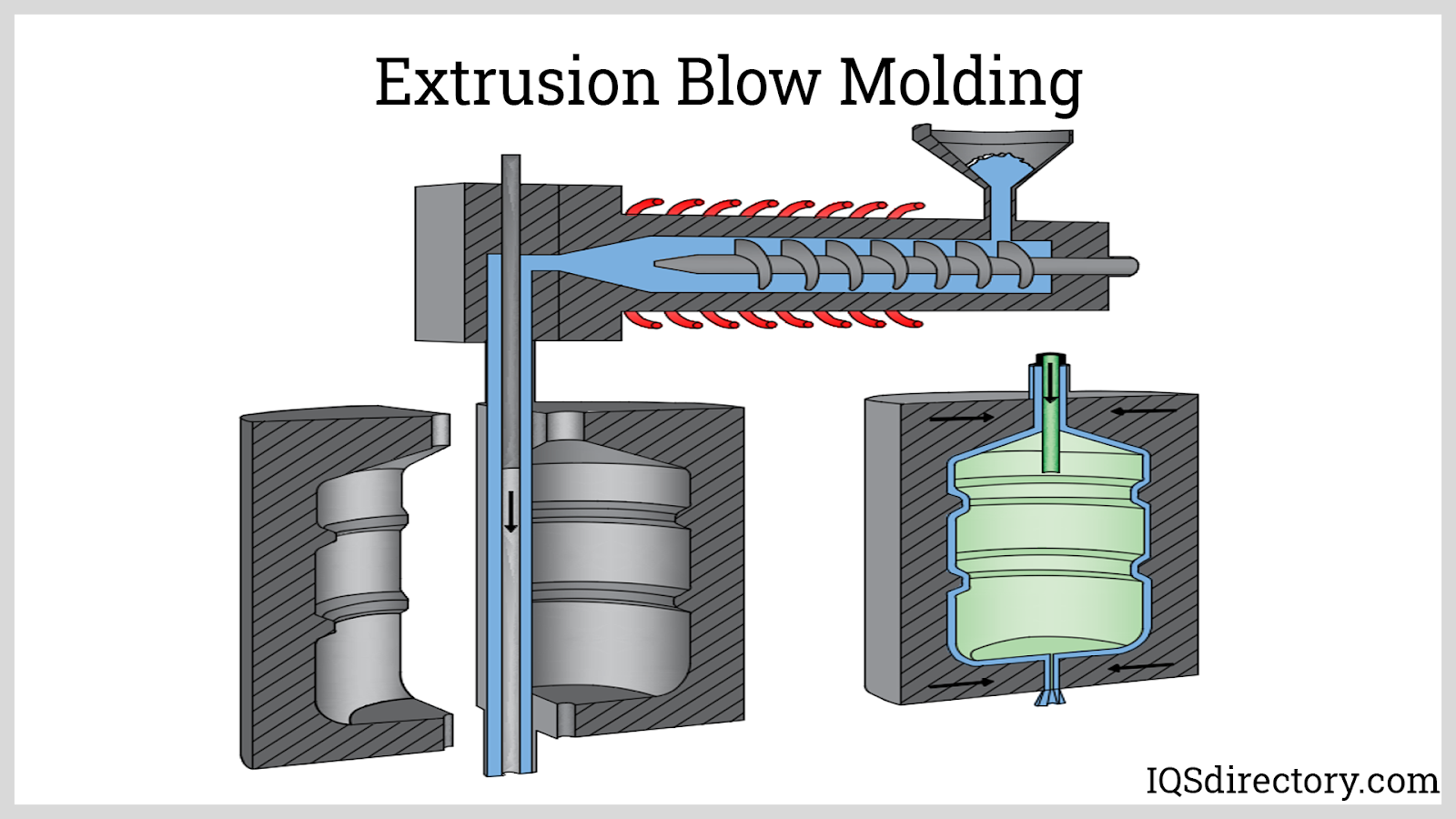

Blow Molding

In this method, the softened plastic compounds are heated and formed into tubes called parison or preform. The preform is then clamped between two dies, cooled, and then the product is ejected from the molds. Hollow plastic products are made from this process by introducing air into the mold. This method creates products such as bottles, water jugs, tube packaging, intermediate bulk containers, and storage tanks.

Rotational Molding

Rotational molding, also known as roto molding, is used for making hollow and seamless plastic products. Containers are made by spreading the plastic melt on the inner surfaces of the mold through rotation. Products such as agricultural storage tanks, drums, carboys, insulating boxes, and trash bins are made from this process.

Thermoforming

In this process, thin plastic sheets are stretched over the mold, heated, and given a three dimensional shape. Vacuum pressure is applied to the sheets to shape it; afterwards, the corners are trimmed. Food packaging, disposable cups, trays, plates, and containers are all made with this method.

Compression Molding

Compression molding is done by compressing plastic resin between two molds. Once the resin is cooled, it is removed from the mold. Internal heating elements are present within the molds that help in softening the plastic. Tubs, bins, trays and bottle caps are made from this process.

Types of Plastic Bins or Containers

Plastic bins or containers are a common part of our everyday life. Some types are as follows:

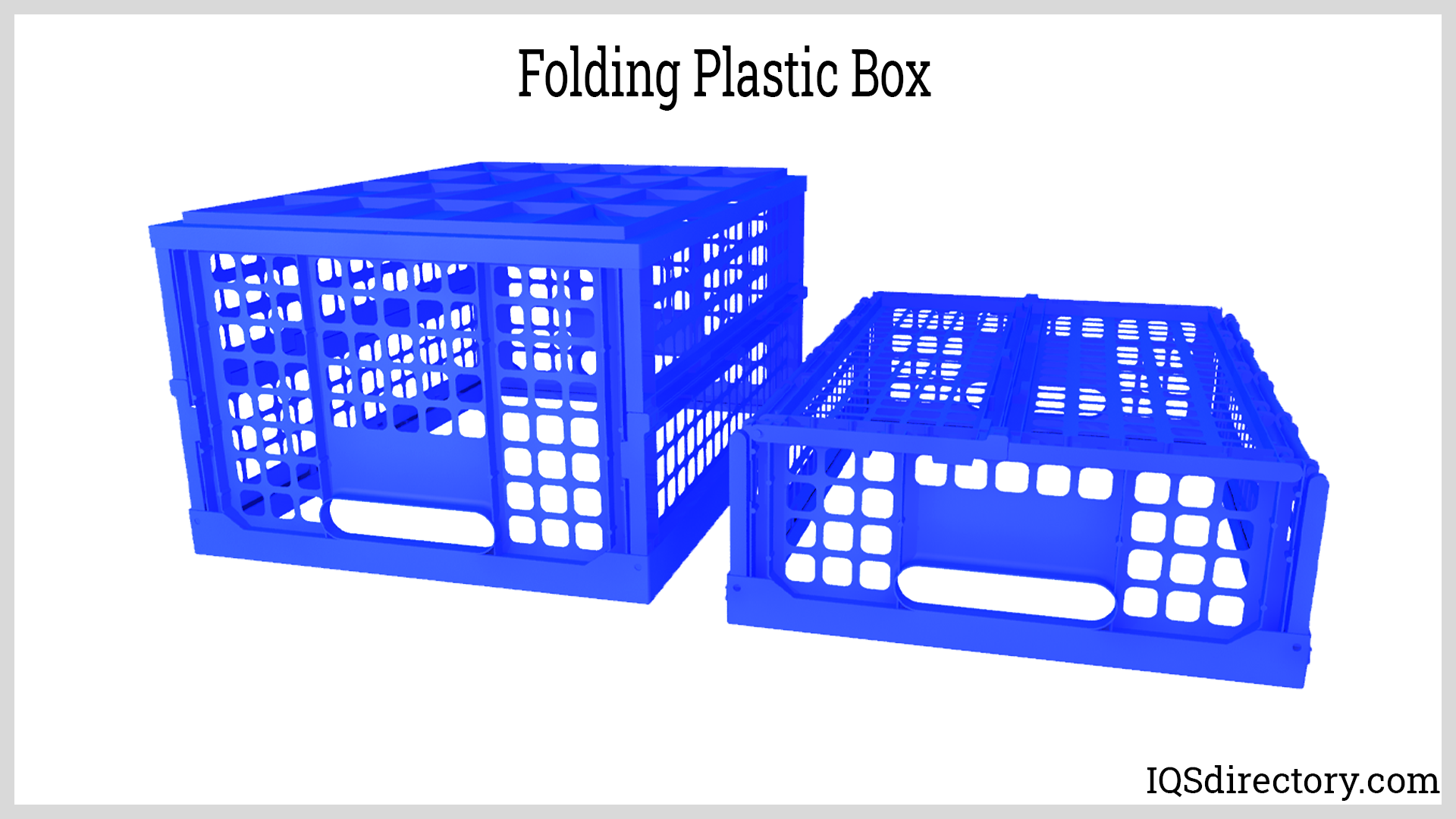

Plastic Folding Boxes

Plastic folding boxes are made from thermoplastic material, which gives a clear view of the product and also protects the product from damage. They are used for shipping heavy duty products.

Plastic Barrels

Plastic barrels are made from HDPE and are ideal for storage and shipping of chemicals, fluids, and other hazardous materials. These are rust- and corrosion-resistant with a long shelf life.

Plastic Gas Cans

Plastic gas cans are used for storing and transporting gas without leak or seepage.

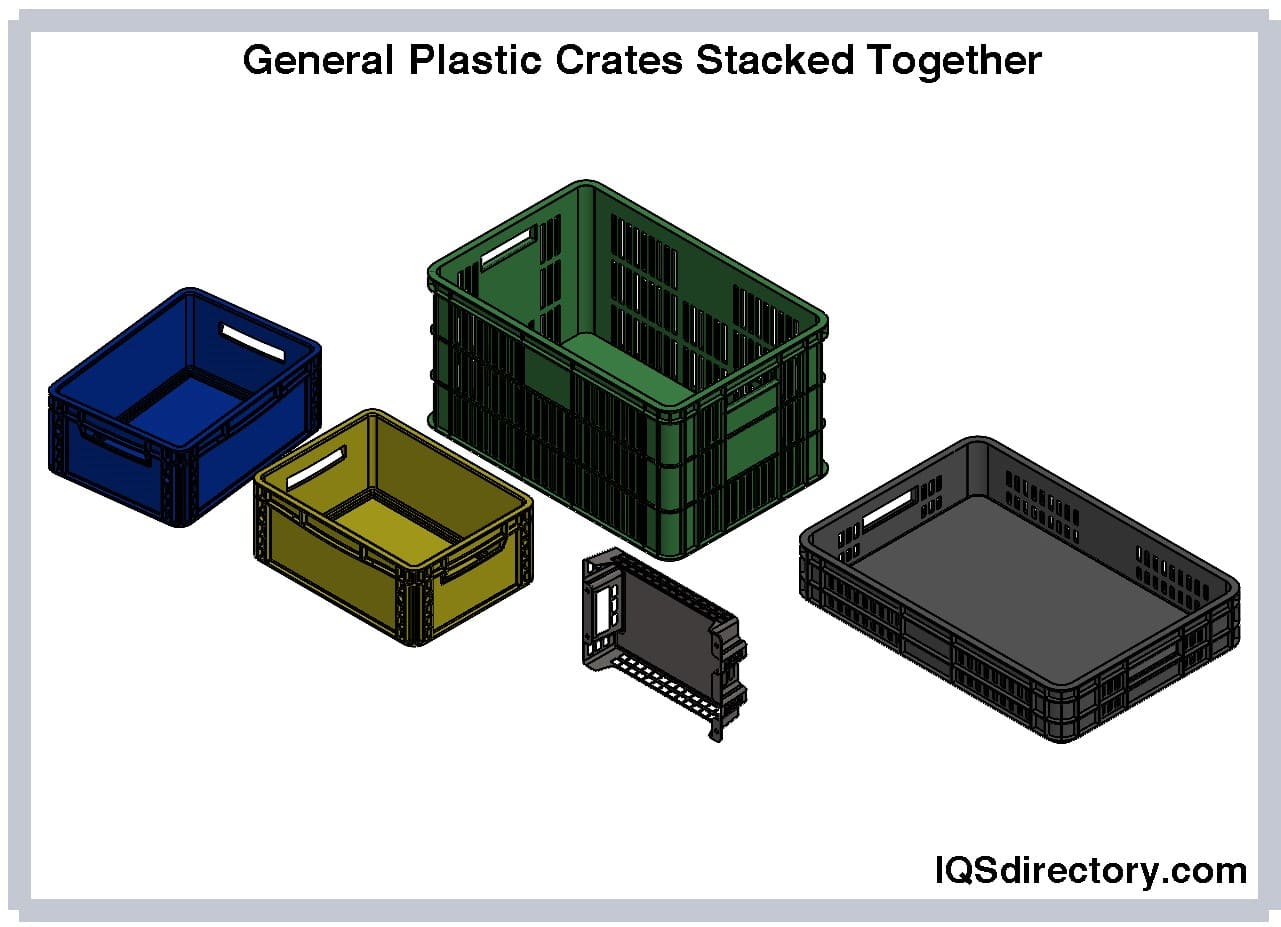

Plastic Shipping Crates

Plastic shipping crates are used for transporting products at long distances. These are sturdy, strong, and durable, and they can carry electrical tools or heavy equipment with ease.

Advantages of Plastic Bins

- Plastic bins are formable and can be shaped easily according to the needs of the client.

- Plastic bins resist chemical and water degradation.

- They are lightweight and highly flexible, with great strength.

- The plastic material has high impact and tear resistance.

- The production cost of plastic bins is low, and they can be recycled and reused.

Choosing the Correct Plastic Bin Supplier

To ensure you have the most positive outcome when purchasing plastic bins from a plastic bin supplier, it is important to compare several companies using our directory of plastic bin suppliers. Each plastic bin supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each plastic bin business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic bin companies with the same form.

55 Gallon Drums

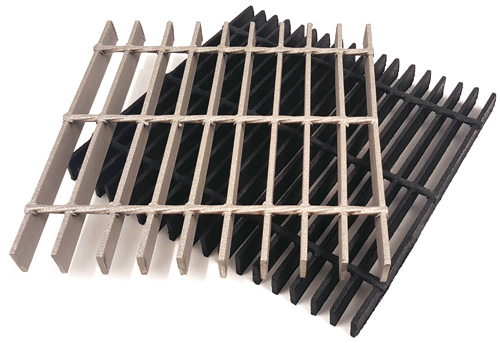

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services