Most other kinds of plastic containers share plastic buckets’ ambiguity of purpose; the words “plastic buckets” are not prescriptive of a specific design or function, but descriptive of a general concept. Read More…

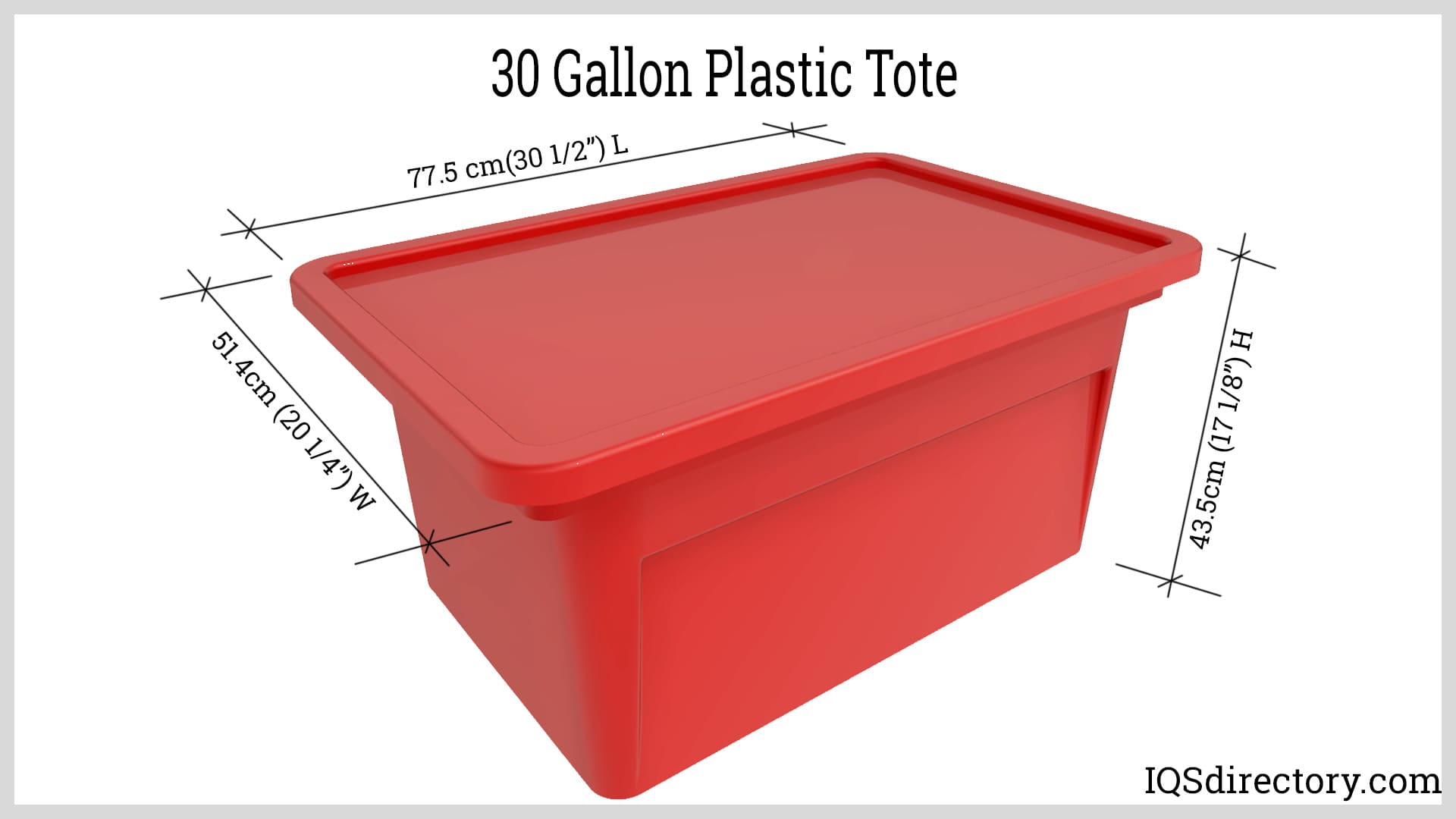

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Plastic Bucket Manufacturers

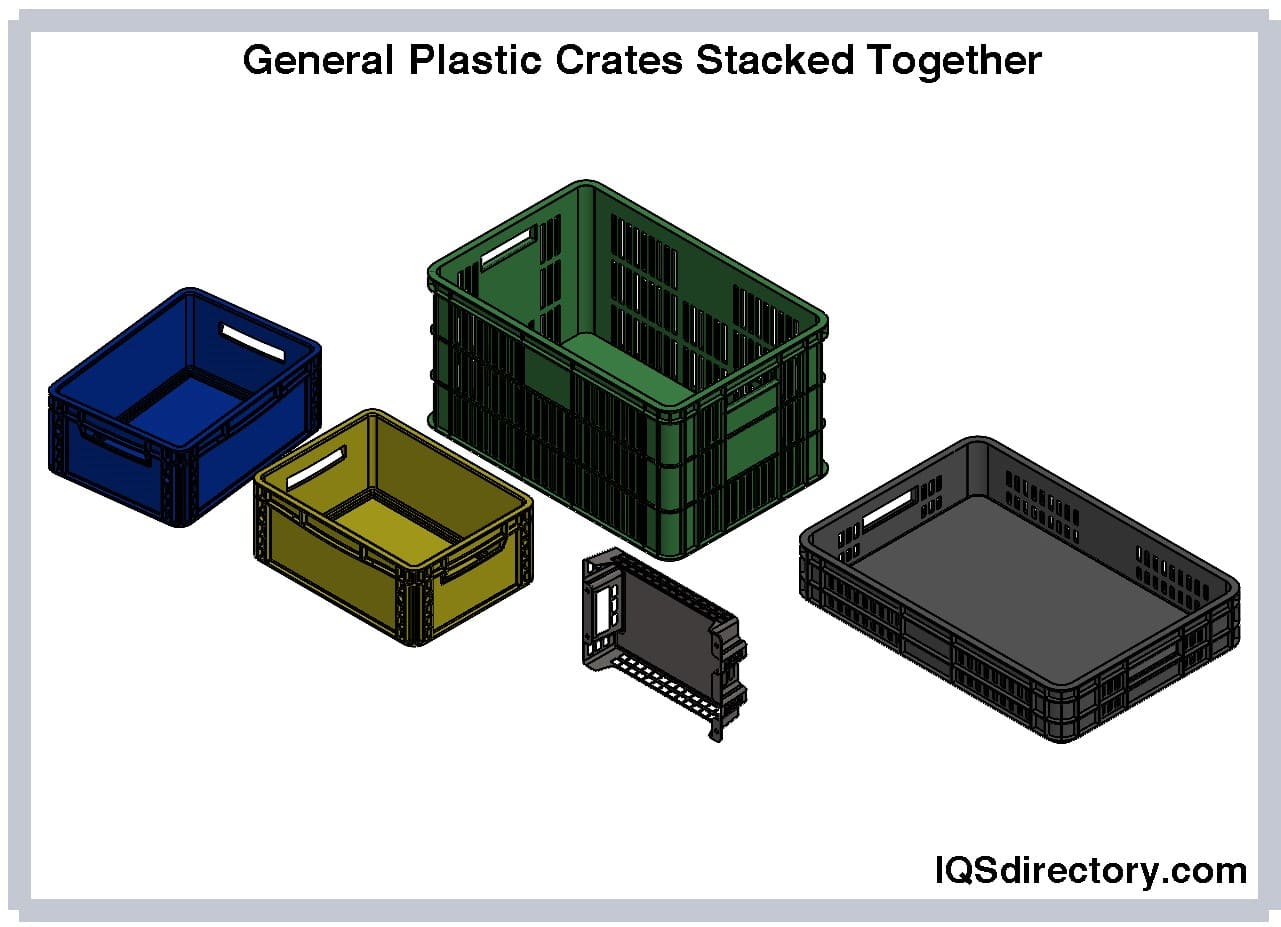

Plastic buckets generally tend to be portable, round containers of small to medium size that are used for the transportation or storage of a range of materials in small quantities. They tend to be smaller than plastic tubs, though there are exceptions; they also tend to be larger than plastic bottles, though there are exceptions. They can be large enough to transport emulsifier on a commercial or industrial scale, or they can be small enough for making beach sandcastles.

The lifespan of some plastic buckets might involve both, given their reusability, light weight and low cost, though this would be more likely if the bucket originally contained consumer products. Most plastic materials' ease of recyclability makes them attractive materials for container construction because many containers are only needed once for the transportation or delivery of a product. Virtually every industry makes some use of plastic containers, and many of those containers are designed as buckets.

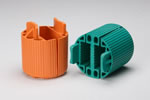

The manufacture of all plastic containers involves either a blow molding or injection molding machine. Many buckets are made out of high-density polyethylene. HDPE is a durable, non-reactive thermoplastic that resists impact and inhospitable climates during transit or storage. In the blow molding process, raw HDPE resin, which in the beginning of the molding process is called stock, is loaded into a hopper. The hopper then directs the stock into a conveyance channel where a large screw forces the stock toward a mold. As the screw turns, the combination of friction and pressure heats the stock.

This heating, combined with extra heat provided by heating elements along the channel, heats the stock to the point of liquefication. At this point, the liquefied stock enters a mold cavity and takes its shape. Compressed air is then blown into the cavity, hollowing out the middle of the plastic mold. Once the molding process is finished, the product is allowed to cool and harden. It is then ejected from the mold, cleansed of imperfections (if they are present) and either shipped or sent for additional processing.

55 Gallon Drums

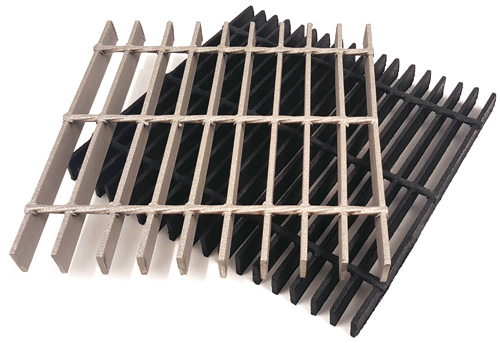

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services