Any plastic material that is used to ship items from one place to another is a plastic shipping container. Plastic containers are excellent shipping solutions because they can be designed to be impact resistant, shatter-proof (this feature makes plastic a better choice than glass in many cases) and weather resistant. Read More…

As a leader in the plastic container & plastic food container industry, Rahway Steel Drum Company supplies plastic storage containers, plastic shipping containers & more, to be used for regulated & non-regulated liquid & solid packaging. Choose from our many sizes from 1 quart to 330 gallons. For 60 years we have been a plastic container distributor of lightweight, space saving, bulk containers.

Jakacki Bag & Barrel, family owned and operated, is a plastic container manufacturer. Their products include pails, pallets, gaylords, drums and so much more.

Container Distributors offers a solution for all of your plastic container needs, including all sizes of new and reconditioned plastic containers, as well as steel and fibre drums. We also carry a wide range of cubic yard boxes and IBC/totes.

Mauser has over a century of experience providing quality plastic and metal drums and IBC's. We offer a wide selection of open head and tight head drums from 15 to 65 gallons, and IBC's from 160 to 330 gallons. Call Mauser for your Industrial Packaging Solutions!

For the past 30 years, Western Industries has been manufacturing plastic containers for a variety of industries, and fulfilling the needs for businesses large and small. At our 350,000 square-foot manufacturing campus, we have the technology and the expertise to manufacture plastic containers of all shapes and sizes, defect-free.

More Plastic Shipping Container Manufacturers

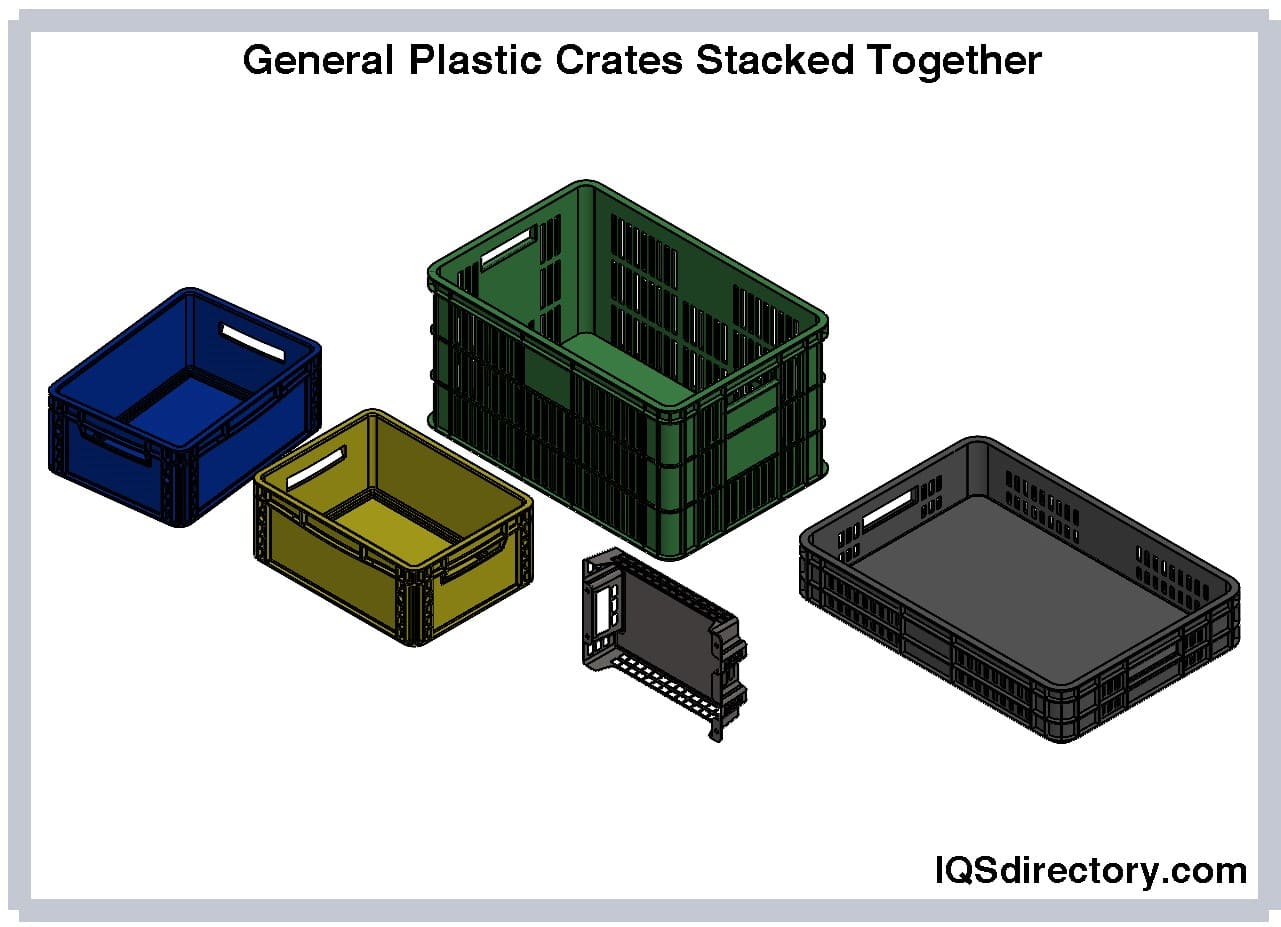

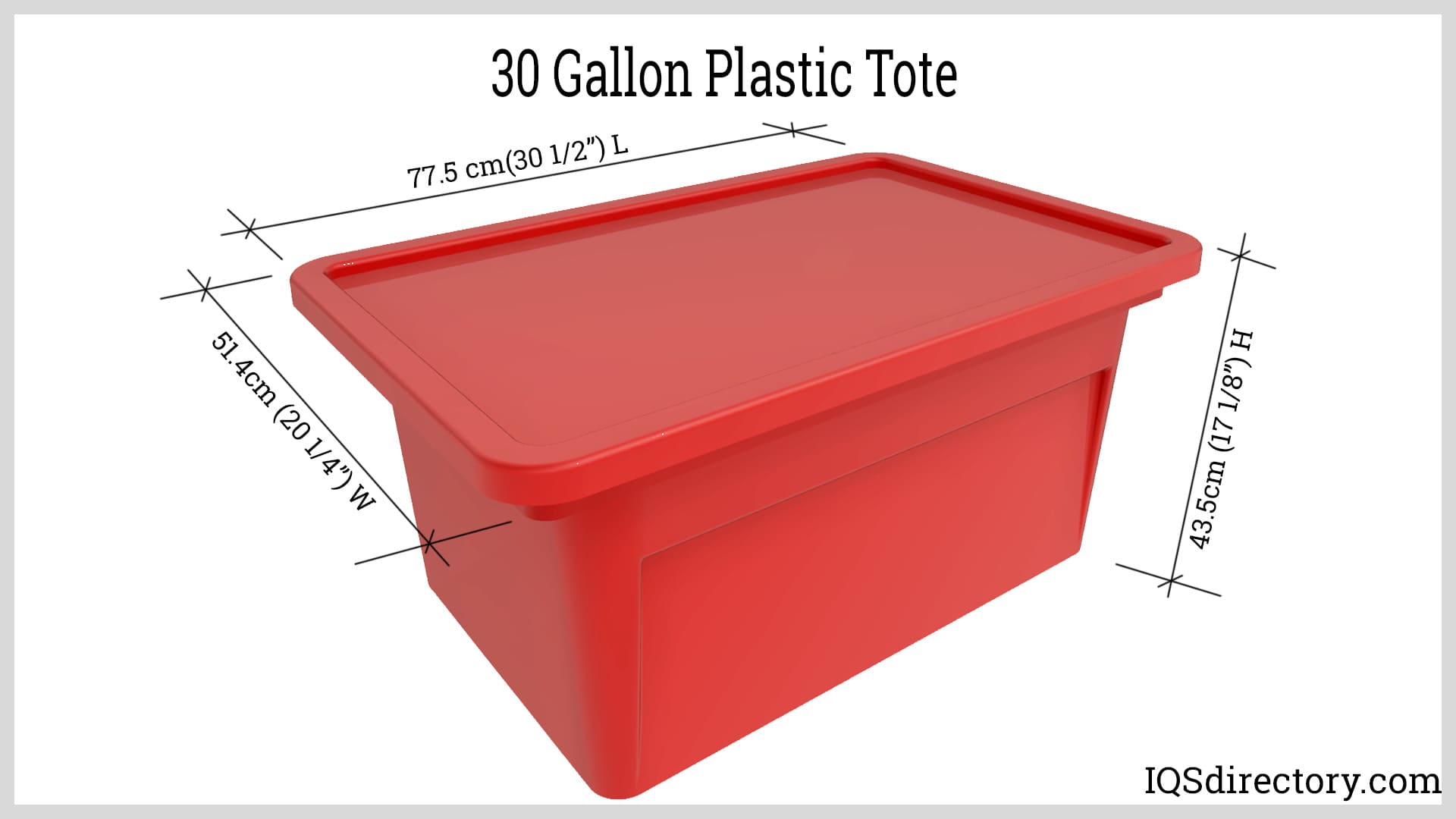

Raw plastic materials are generally inexpensive, which makes plastic shipping containers the smartest economic choice. Because plastic can be molded into any conceivable shape, customized plastic containers, which can be made to fit the contours of the items they are transporting, are excellent for transporting delicate or sensitive materials.

Plastic shipping containers are often reusable, but in the case of damage or excessive wear, many varieties of plastic shipping containers can be recycled. Some plastic shipping containers are designed to be air-tight; these containers can be used to transport products like paper or electronics, both of which require protection from weather conditions while in transit. Ventilated shipping containers can house living cargo like plants and animals.

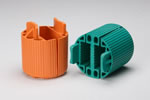

All plastic shipping containers are made with thermoplastic resins and are created during a molding process. Plastic boxes can be either blow molded or injection molded. In both cases, the molding machinery would begin with a collection of raw plastic resin (which is called stock) that is loaded into a hopper and directed into a conveyance channel.

A long screw turns in the channel, forcing the plastic toward the mold. As it turns, the combination of friction, pressure and heating elements along the length of the channel liquefies the stock. Once the stock is liquefied, it can be molded into any shape. At this point in the molding process, the plastic will either be injected into a mold (this is called injection molding), or it will be forced into a mold cavity along with compressed air (this is blow molding).

Generally speaking, the thinner the construction of the plastic box's walls, the more likely it was to have been created by blow molding. Once the molding process is complete, the plastic is allowed to cool and harden. Then it is ejected from the mold, cleansed of imperfections (if they are present) and either sent for shipping or for additional processing.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services